Welcome To MED Engineering

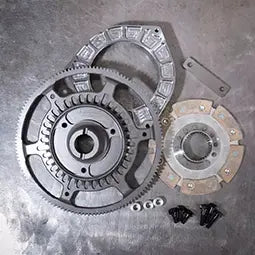

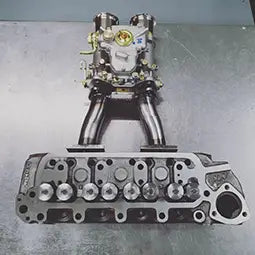

MED Engineering is your go-to place for high-quality classic Mini spares in the UK and worldwide. With a rich history dating back to 1981, we've long been a trusted name in the world of the Classic Mini, Mini Cooper and Austin Healey Sprite/Midget. Whether you're a proud owner of a classic Mini Cooper or simply passionate about preserving the heritage of these iconic vehicles, we have you covered.

Our Top Picks

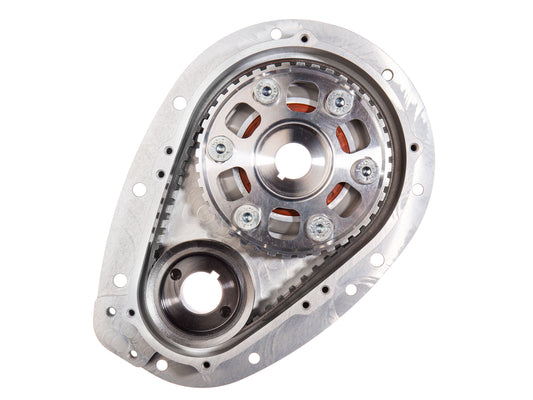

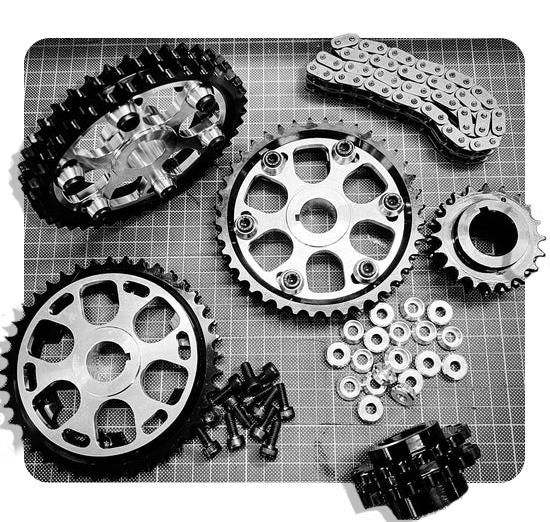

Don't miss our top-performing products of the year so far! These are customer favourites, carefully selected to provide an exceptional experience. Discover what everyone has been talking about and find the best product for your needs.

Discover the Latest News at MED Engineering

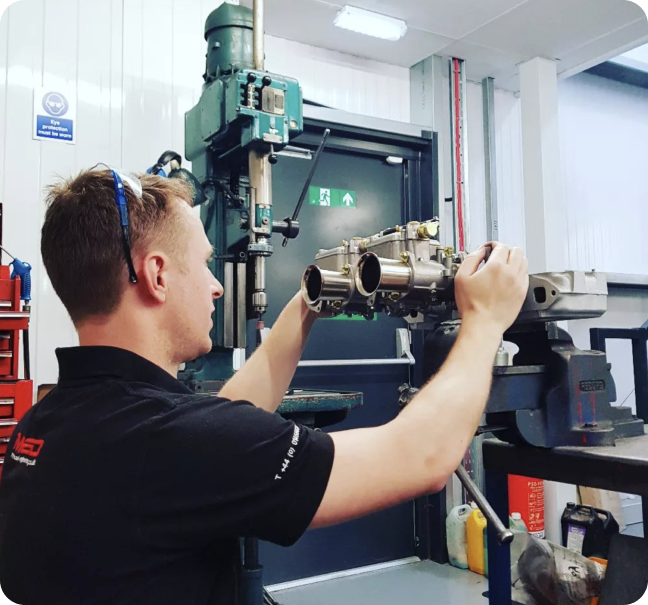

Follow Us On Social Media

Stay up to date with the latest updates by following MED. We invite you to join our community

and share your classic Mini stories and experiences with us using the hashtag #MEDEngineering Together, we celebrate the enduring legacy of the classic Mini and continue

to drive innovation and improve performance.

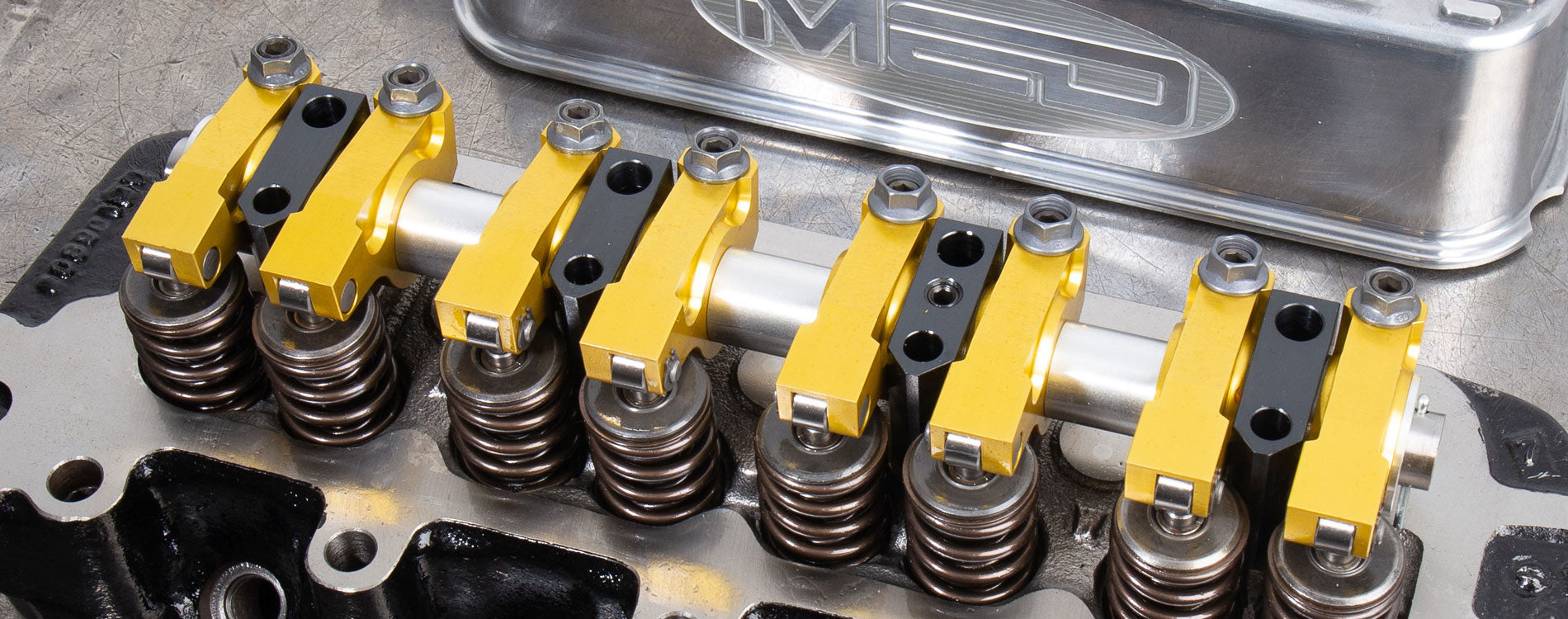

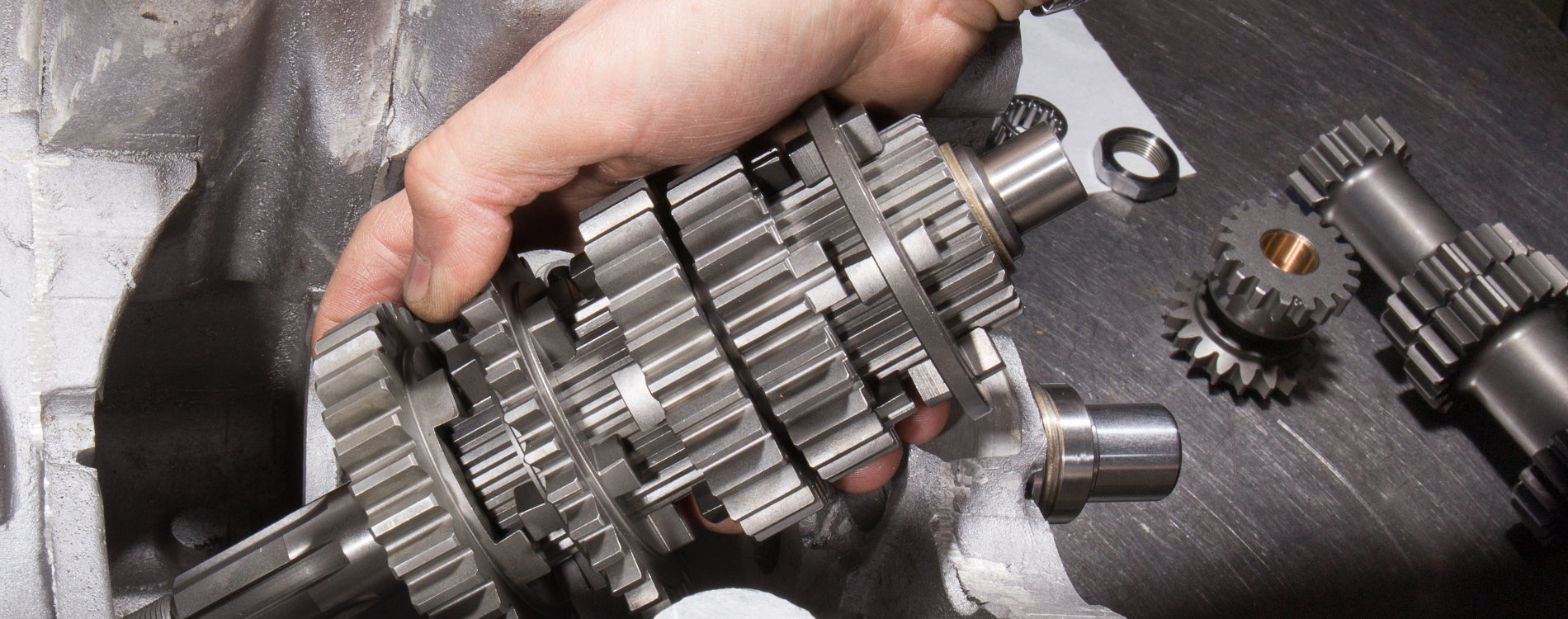

With over four decades of experience, we're not just a company; we're enthusiasts, engineers, and trusted partners on your classic Mini journey. Our commitment to providing high-quality classic Mini parts and classic Mini spares is unwavering. Whether you're restoring a vintage Mini to its former glory or seeking to boost its performance, MED Engineering is your reliable source for all things classic Mini.

Read more

Customer Reviews

Preserving the Legacy: A Journey Through Time with MED Engineering

The classic Mini, an iconic British automobile, was born in 1959 when the British Motor Corporation (BMC) introduced the Morris Mini Minor and the Austin Seven, two nearly identical compact cars designed for city driving. This revolutionary design, featuring a transverse engine, front-wheel drive, and a compact body, was the brainchild of Sir Alec Issigonis, and later enhanced by John Cooper, making it a worldwide success. The classic Mini continued to evolve throughout the years, with various models and improvements. Its small size, excellent manoeuvrability, and affordable price tag made it immensely popular, not just in the UK but around the world. It quickly gained a reputation for its charming and timeless design, becoming an iconic symbol of British automotive engineering. Fast forward to today, the classic Mini has stood the test of time and remains a beloved classic car among enthusiasts and collectors. Its enduring appeal is attributed to its unique blend of style, practicality, and a sense of nostalgia. Many classic Mini owners take pride in preserving and restoring these vintage gems, and the availability of high-quality spares and performance upgrades, like those offered by MED Engineering, is crucial to keeping these classic cars on the road. MED Engineering, with its history dating back to 1981, plays a significant role in the classic Mini community. As pioneers in historic motorsport, we have been at the forefront of enhancing A-Series engines and developing performance upgrades for classic Minis. Our commitment to providing top-quality classic Mini parts and spares ensures that these beloved vehicles can continue to delight enthusiasts and drivers for years to come.