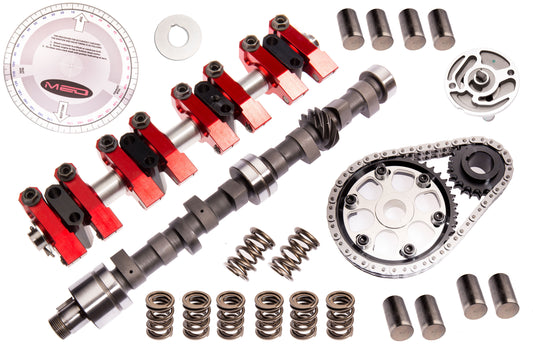

MED 1.3 ROCKER SET

Technical Video:

Description

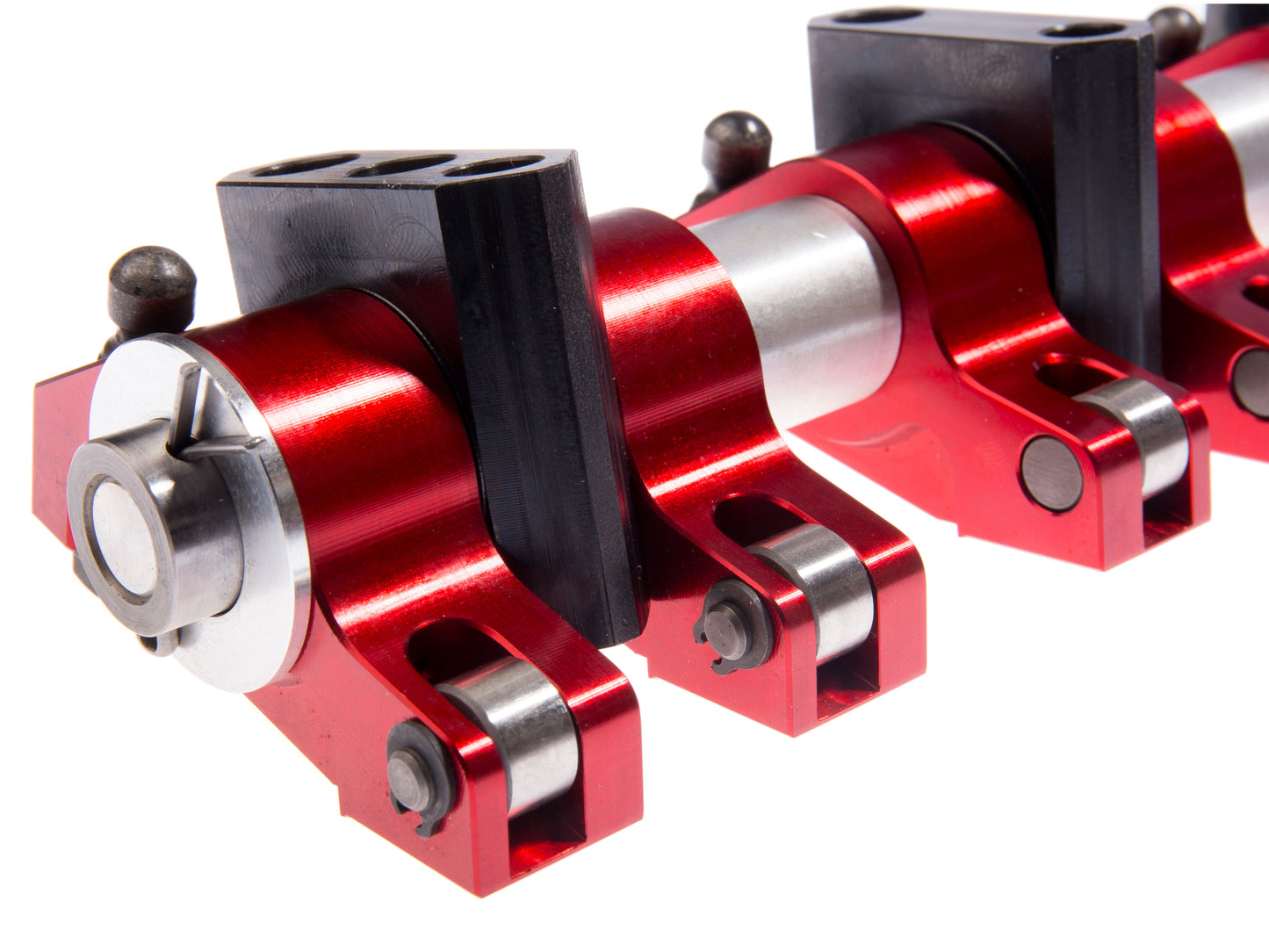

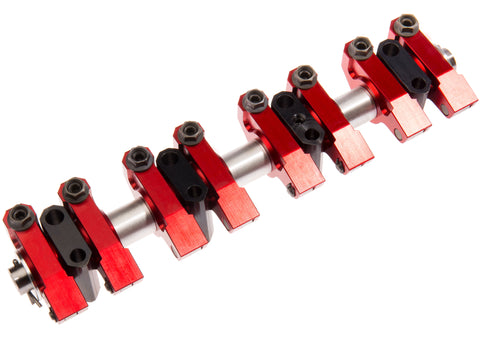

MED roller-tip rockers give far more consistent valve lift across the head than the standard rockers, with an enlarged rocker shaft and adjusters for extra strength.

Cylindrically-ground rollers in the arm tips reduce side-loading of the valve stems to improve valve and guide longevity, while also reducing friction.

A host of unique design features equate to the highest quality 1.3:1 roller-tip rockers on the market. They're trusted by leading engine builders worldwide for all performance A-Series, mild road to full race.

Please see the additional information tab for more technical details.

Design features:

- Uprated 17mm diameter rocker shaft for greater surface contact between the shaft and rocker arms.

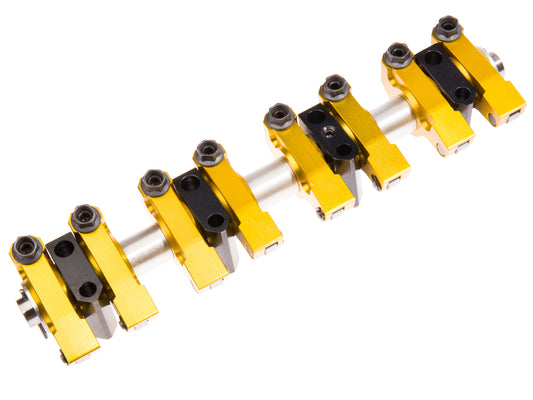

- CNC-machined heavy-duty 7075 aluminium rocker arms for extremely precise valve lift across the head.

- High quality steel rocker posts, chemically black coated.

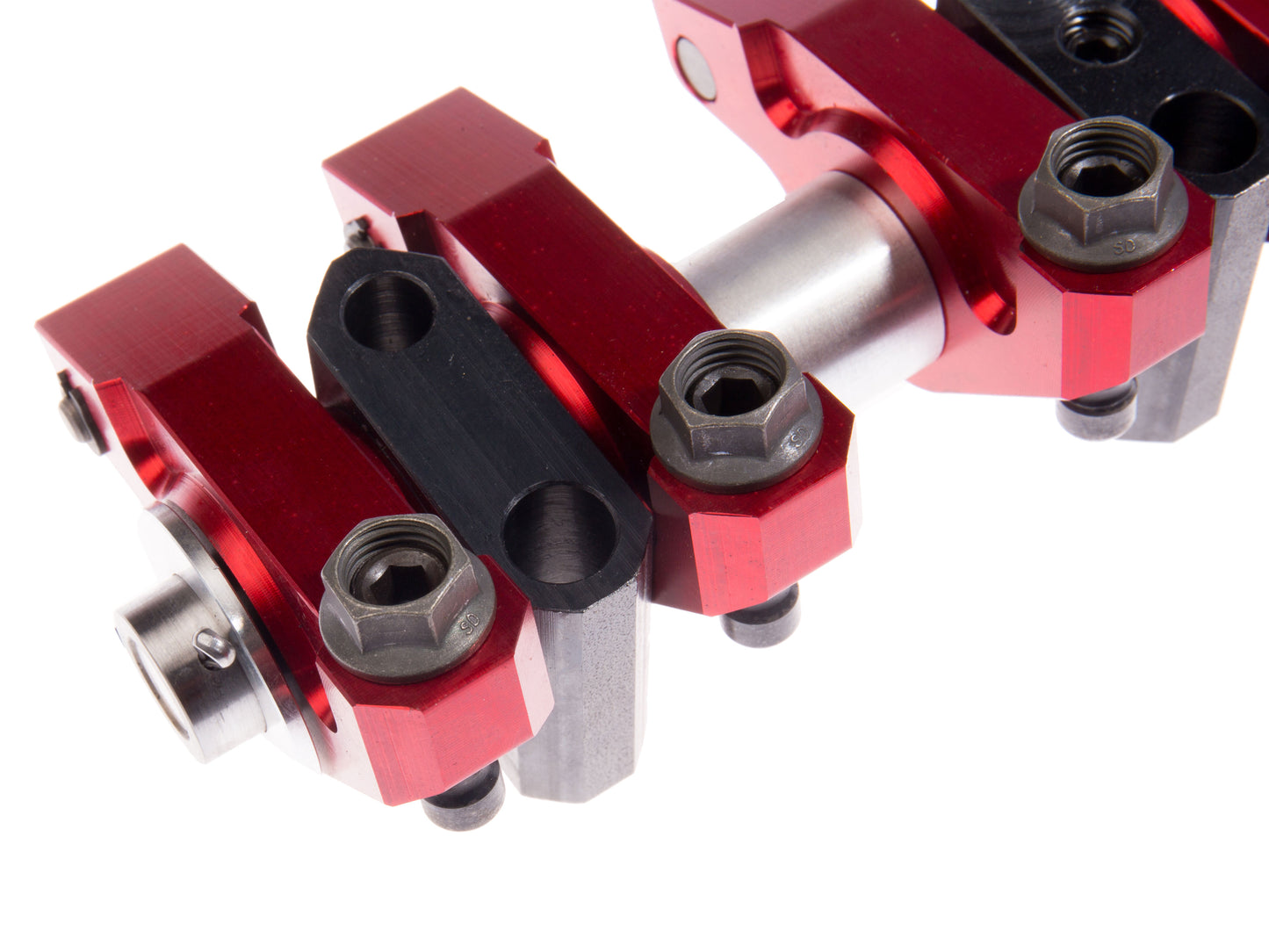

- Enlarged 3/8-inch UNF rocker adjusters with lightweight aerospace 'K' lock nuts.

- 3/16-inch hex socket adjustment in place of the regular flat-blade screwdriver slot.

- Fully assembled with alloy rocker spacers, end washers and split pins.

Please note - the arm spacing of our rocker assemblies makes them suitable for 1275, 970(S) and 1071(S) based engines only. They will not suit small-bore (850, 998,1098 etc) cylinder heads.

For extra clearance we would highly recommend an MED rocker cover kit and ARP head stud set to accompany these rockers.

You may also require a set of rocker post shims to perfect valve lift and centralise the rockers over the valves when the head/block faces have been machined.

Additional Information

Benefits of the MED roller-tip rockers

Standard rockers rarely give consistent valve lift across the head, even when new. After many years of use and wear, lift is likely to be even more inconsistent, so while 1.28:1 is generally given as the standard rocker ratio, a quick check of the valve lift will usually show otherwise. Optimising every aspect of the engine will enhance performance, and the 1.3 rockers should give marginally more lift than standard.

Roller tips reduce side loading of the valve stems, in turn reducing friction whilst also improving valve and guide longevity.

Add to this extra stiffness across the shaft, trouble-free tappet adjustment from enlarged adjusters, and you have an excellent performance upgrade.

Intended fitment

The MED roller-tip rockers are designed for the 1275 A-Series cylinder head, but will also suit the 1071 and 970 Cooper S engines, which share the same valve stem spacing. We have heard of customers experimenting with arm location and spacing to suit small-bore heads, but it's not something we would recommend. Of course if you are running a 1275 head on a small-bore block then these will fit no problems.

If you are running a more exotic race head with offset exhaust valves, you will need to upgrade to the LDX rockers, which are available in a special offset design.

1.3:1 vs 1.5:1 rockers

All MED fast road and race camshafts are optimised to work best with 1.5:1 rockers, however there is still strong demand for 1.3:1 rockers. If you're already satisfied with the performance of your engine, the 1.3 rockers will retain much of the same powerband but with all of the benefits listed above. For those in search of a bit more power, ultimately 1.5 rockers will achieve this.

Some race series specify a strict valve lift, so the 1.3s may be ideal in this case. They are also very popular with forced induction engine builders.

Optional extras

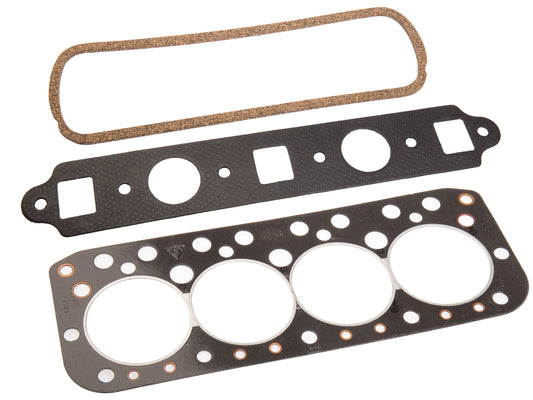

We always recommend changing the head gasket when removing the rocker assembly, as you may end up disturbing the gasket while loosening off the rear stud nuts. Arm clearance can sometimes be an issue when using the standard head studs and nuts, so an upgrade to ARP head studs and nuts is a good plan.

The standard steel rocker cover will clear these rockers, but aftermarket aluminium types will usually catch the arms on the rear corners. So either machine out material from the inside of the cover or upgrade to an MED rocker cover, which comes pre-machined internally to suit.

Related Products