MED MULTI-WEB CRANKSHAFT KIT - INLINE

Technical Video:

Description

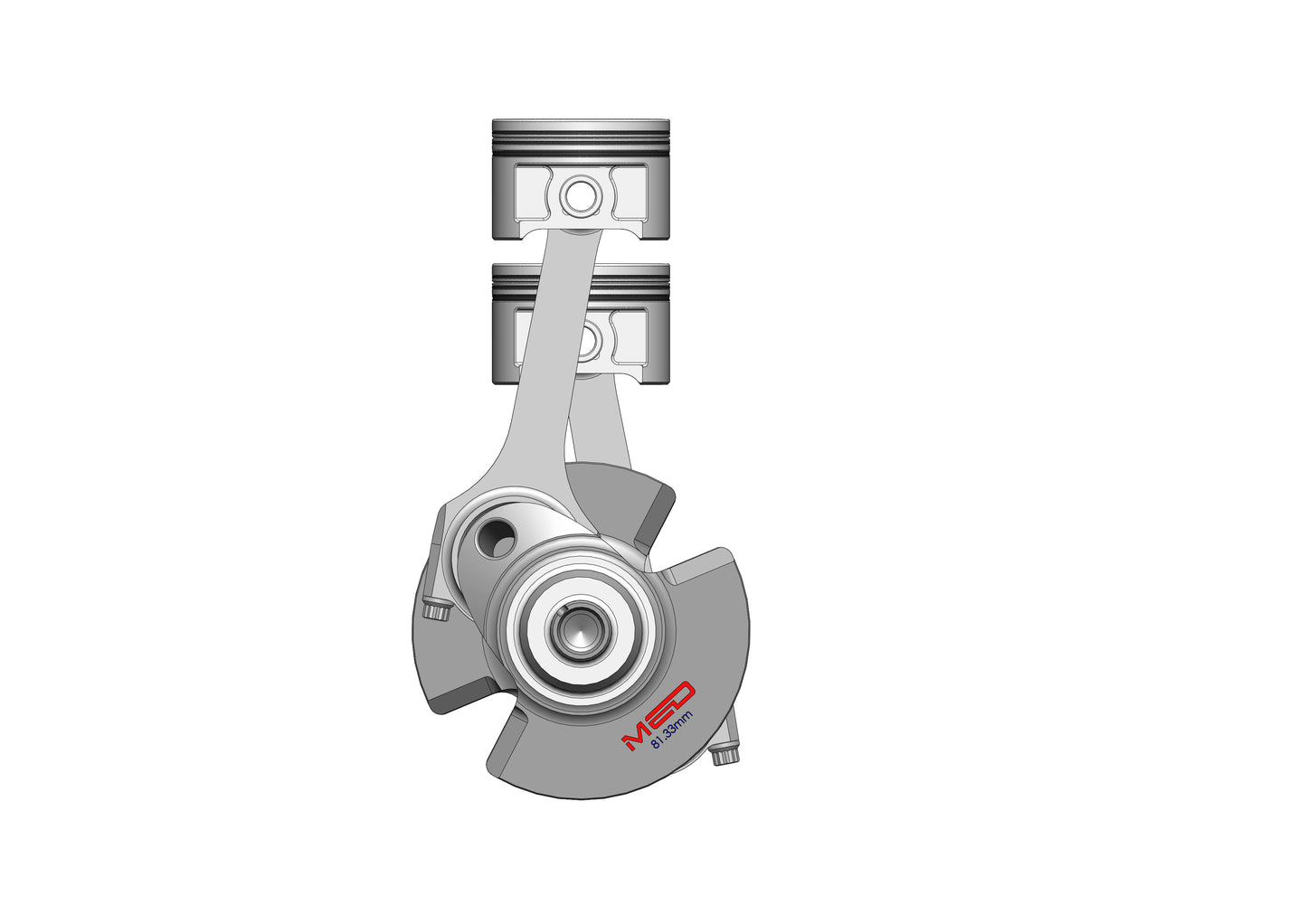

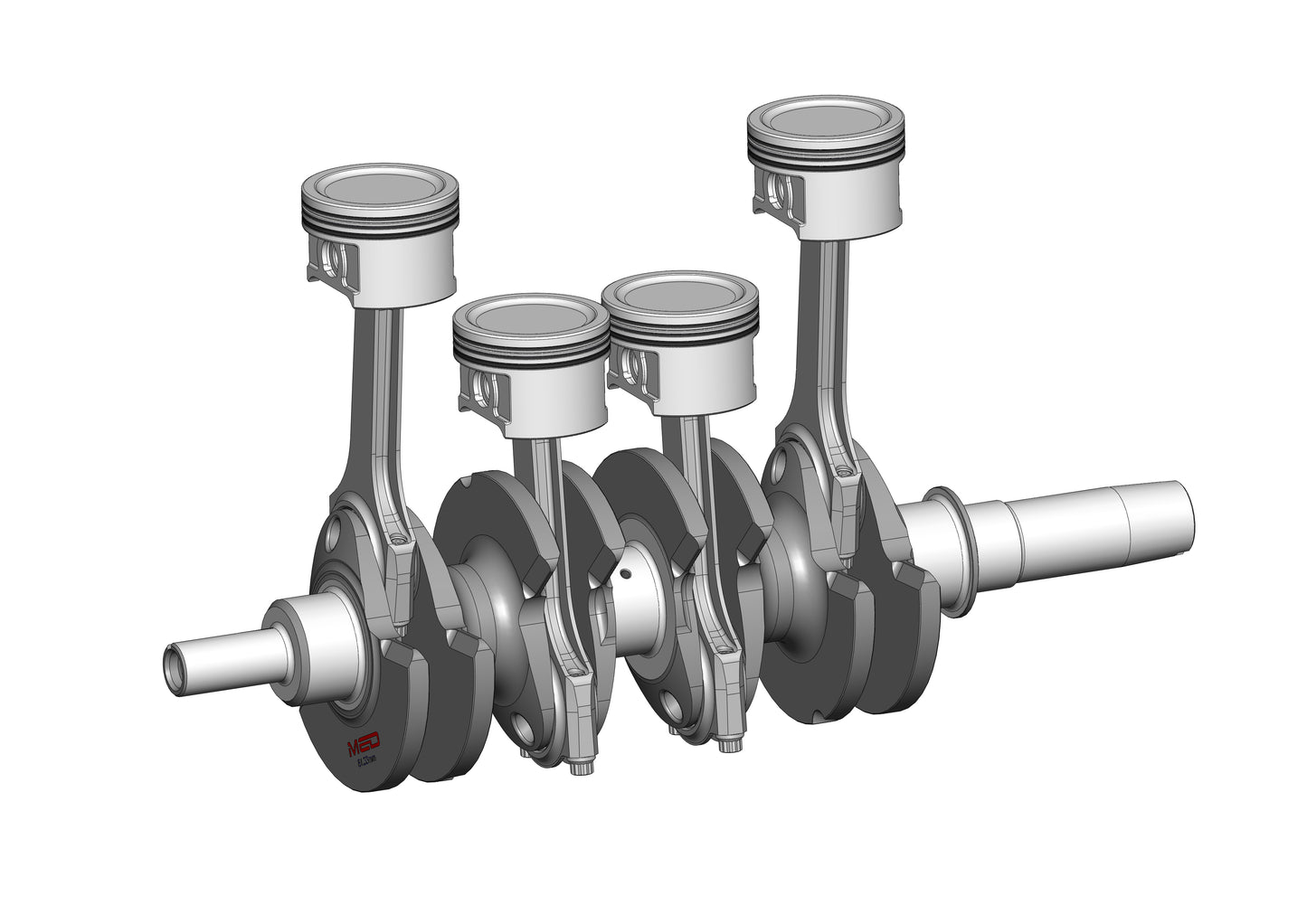

The MED Multi-web crankshaft features an almost perfect 50/50 balance factor, which in conjunction with the exclusive six-inch non-offset conrod, eliminates rotational twisting and piston side loadings normally associated with the standard A-Series configuration.

With this crankshaft package, the engine will achieve a higher rpm and in turn maintain a higher bhp for longer.

The crankshaft is only supplied with conrods, as these feature a narrow width, large diameter big end journal size for weight reduction and strength.

Crankshaft kit main features;

- Engine configurations from 1293cc to 1380cc

- Eight full knife-edged counterbalance webs

- Two extra 'ghost' main bearings for greater strength

- Narrow width, large diameter and hollow-drilled big end journals

- Extra long square-section key way

- Steel non-offset H-section 6.000" conrods

- 18mm bushed conrod little end journals

- ARP conrod fixings

- Omega forged lightweight, short-height pistons

- ACL bearings and thrusts

Each crankshaft is supplied with a set of Omega forged lightweight short-height pistons to complete the competition-grade package. These are available in a number of different configurations, so a member of our sales team will contact you after purchase to confirm.

A set of ACL Race main and big end bearings are included alongside ACL thrust washers.

Please note - the timing gear end has a carefully machined radius for extra strength - please be sure that your timing gear sprocket has a matching radius or damage will be caused on assembly.

Please see the additional information tab for frequently asked questions.

Additional Information

Why is an MED multi-web steel crankshaft the ultimate?

The counterbalance effect is especially impressive with the multiweb, even more so than the popular EN40B steel crankshaft. An improved counterbalance effect helps to reduce the 'whip' often encountered with the three main bearing A-Series crankshaft, to much improve longevity and performance at higher RPM levels.

This unique design utilises a narrower yet larger diameter big end journal size for extra strength along the crankshaft. There's also a unique deisgn of non-offset conrods to reduce the effects of excess piston side loadings.

The EN40B steel crankshaft is best for when regulations do not permit a multiweb crankshaft – for all else this is the ultimate setup.

Is this a standard replacement?

Yes it will fit a standard 1275 Midget/Sprite/Marina block. We would highly recommend a steel main cap upgrade, which will then require line-boring.

The narrower big end journals mean that standard type conrods do not fit; therefore we can only supply the crankshaft as a complete package with conrods and pistons.

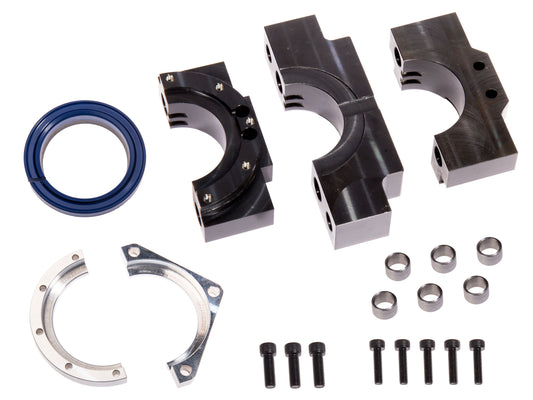

Do I need to use steel main caps?

Ideally, yes. We would highly recommend an MED four-bolt steel main cap set, AFS studs and line-boring of the block when upgrading to a steel crankshaft. On a road car, an MED centre main strap kit may suffice, but it's not the ideal arrangement when using a such a high-end crankshaft.

Are different stroke lengths available?

We only keep a standard 81.33mm stroke version for the inline engine, to give engine capacities from 1293cc to 1380cc.

Which pistons do I need?

The bore size may depend on your race regulations, the block you have to work with, or personal preference. We can supply a range of different bore sizes and crown designs to create your desired compression ratio and capacity. Compression height is shorter than standard at 1.248", to account for the longer conrods.

Can you make me a custom steel crankshaft?

Unfortunately with the design, drawing and machining costs involved in producing a custom design crankshaft, it would prove too expensive. However, we have developed our crankshaft designs over many years using decades of A-Series engine experience, so you can be assured of the best possible setup for the vast majority of applications.

Related Products