OMEGA 998 FORGED LIGHTWEIGHT FLAT TOP PISTONS

Description

The MED/Omega forged 998 semi-slipper piston is perfect for high performance small-bore engines, the plus-0.020" particularly successful in the Mini Se7en race series, and plus-0.040" in Ministox and autograss.

CNC machined from lightweight alloy forgings, the pistons have been designed to be as light as possible, at only 236 grams for the +20 size including 5/8" pin and rings.

Tech spec

- +0.020" and +0.040" sizes for the 998cc engine

- Super lightweight semi-slipper design

- High strength for full competition usage

- Flat-top crown

- Made in the UK exclusively for MED

- Lightweight 5/8" floating gudgeon pins

Please see the additional information tab for more detail and advice.

For use with either fixed or fully floating pins and supplied with a set of special wire circlips.

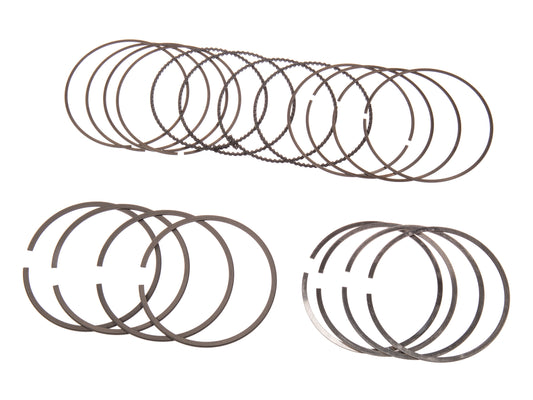

Supplied as a balanced set of four with gudgeon pins, clips and piston rings, which are also available separately.

Additional Information

Production process

High silicone alloy is first cut to billet size and the faces machined to a smooth finish. Each billet is pre-heated in an air-circulating furnace to a temperature close to the operating temperature of the piston crown, then compressed into a rough shape using Omega's in-house forge and custom-designed dies.

The specific temperature, together with tightly controlled speed of the forging process, gives a dense and very fine grain structure to the piston for high strength and superior fatigue life.

Any excess material is then removed before the forgings are heat-treated and wet blast cleaned. From here each piston is subject to a highly developed process of CNC machining, with constant measurement and quality control checks by experienced perfectionists.

Once final machining is complete, the pistons are engraved with a model and batch number, cleaned and sorted into matched weight sets. It's a time-consuming process to create such a high quality product, but the end results are well worthwhile.

Frequently Asked Questions

Will these pistons suit standard 998 conrods?

You will need a set of conrods with bushed 5/8" little ends. Most later 998s had these fitted as standard, and most, if not all aftermarket steel conrods.

What engine cc will these oversize pistons result in?

These would increase the capacity of a 998 to 1014cc at +20 and 1030cc at +40.

Can you tell me what compression ratio these pistons will give?

The pistons are only one part of the equation, so it would be inaccurate to supply a static compression ratio figure without knowing more information on the engine build. If you can email us with the cylinder head chamber volume, head gasket type and the deck clearance figures, we will be able to calculate this for you, and make further recommendations.

Are these only suitable for race engines, or can I use them on the road?

It depends - these are predominantly used in competition A-Series engines, where the higher operating temperatures give a greater expansion rate. As such, they will run marginally larger bore clearance to standard-spec pistons. If the engine is built to a similar spec to a competition engine then it will be absolutely ideal on forged pistons.

Is there a recommended bore finish?

Yes, we suggest plateau honing with a cross hatch angle of 35-40 degrees. After honing with either conventional (#220 - #280 grit) or diamond stone (#325 - #550 grit), finish by smoothing the surface with a fine-grit conventional abrasive (#400 - #600 grit) or sweep the bores with a flexible brush or a nylon bristle plateau honing tool. This is necessary to get rid of jagged peaks and folded and torn material. Your machine shop may have different preferences.

What is the recommended bore clearance and piston ring gap?

For forged Omega pistons we would recommend a skirt clearance of 0.004". The largest diameter of the piston should measured with a micrometer, 90-degrees to the gudgeon pin, three quarters of the way down the skirt. The recommended ring gap (top and second ring only) is 0.010-0.012".

Can I run the +40 size in a Mini Se7en?

Always check the latest technical regulations, but as a general rule, UK-based Mini Se7ens are limited to +20 and National Ministox to +40.

Can the pistons be dished to reduce the compression ratio?

We would not recommend this, as the crown thickness is at the absolute limit for reliability. Look instead at enlarging the combustion chambers in the cylinder head.

Related Products