MED ST3 ULTRA LIGHT ASSEMBLY

Description

The MED Stage 3 Ultra Light Assembly includes an EN8 steel flywheel, backplate and MED race paddle clutch plate. It's the ideal setup for competition Minis producing up to 135lb.ft torque.

The package is expertly assembled, centralised and dynamically balanced to order.

Assembly contents:

- MED EN8 Ultra Light steel flywheel - 3.66kg.

- MED EN8 Ultra Light steel back plate - 1.32kg.

- MED race paddle clutch plate.

- Grey clutch diaphragm.

- 9x MED clutch drive straps.

- 6x MED EN16T steel drive bolts.

- Fully assembled and centralised in-house with dynamic balance.

Flywheel Specification

The MED Ultra Light is CNC machined from EN8 billet and weighs just 3.66kg, a substantial saving compared to standard factory flywheels, which can weigh over 7.5kg! In fact, the complete St2 assembly weighs less than the standard flywheel alone, at an impressive 6.8kg.

Reducing flywheel mass improves the Mini's acceleration considerably, more so than the weight loss alone.

As a result, installing the MED Ultra Light kit will make the car accelerate faster, feel more responsive, and is one of the most cost-effective performance upgrades you can make.

This flywheel can be supplied with a 107-tooth inertia ring gear to suit early style starter motors, or the later 129-tooth pre-engaged design, which is CNC machined into the flywheel itself as per the EN24T X-Lite.

Alternatively we keep High Torque Starter Motors to match.

To install without disturbing the balance, remove the large washer and spring clip from the diaphragm and there is no need to disassemble the clutch/flywheel to install the bolt.

We would suggest upgrading to the St2 X-Lite package if you are running an EN40B steel crankshaft.

Please see the Additional Information tab for further advice.

Additional Information

Flywheel compatibility

Upgrading to an MED steel flywheel not only saves weight, but also gives a more durable surface on which to grip the clutch plate. The lighter the flywheel, the faster the engine will be able to increase/decrease RPM, making it more free-revving and responsive to throttle input.

Our lightest possible clutch and flywheel setup (X-Lite) is ideal for a competition car, whereas a road car will benefit from more flywheel mass to retain drivability in traffic.

The MED EN8 Ultra Light is therefore an excellent choice for performance road and trackday cars - lighter than standard yet still usable on the road. It is also the choice for Mighty Mini and Mini Se7en S-Class race cars.

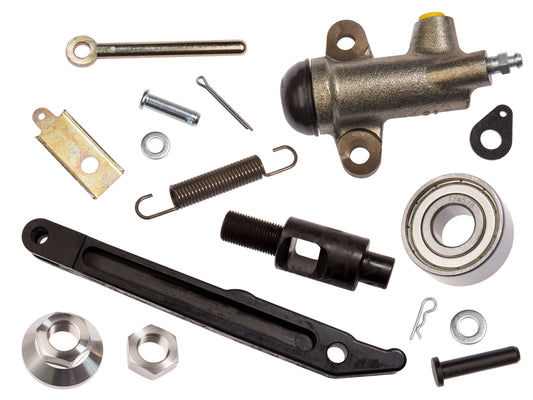

This flywheel will suit all transverse A-Series engines (Mini/Metro) with a pre-Verto clutch setup. It is possible to convert from Verto to pre-Verto by purchasing the MED Heavy Duty Clutch Operating Kit. Please note - this will not suit fuel-injected Rover Minis. See the MED SPi Flywheel or MED MPi Flywheel for these cars.

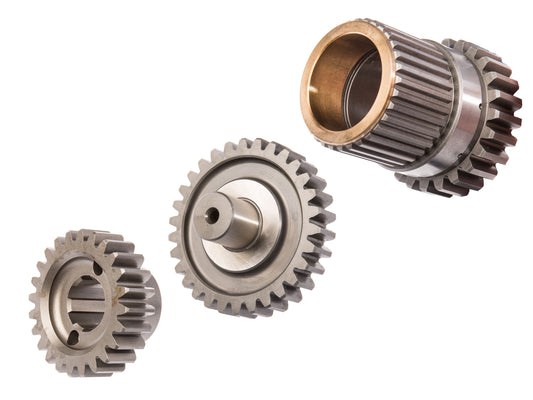

Pre-engaged or inertia?

This relates to the ring gear and starter motor installed on your Mini. Inertia is the original style starter motor that uses a separate solenoid unit on the inner wing, whereas pre-engaged has an in-built solenoid. If you have one of our High Torque or Micro starter motors, simply choose the correct flywheel to suit.

For reference, pre-engaged flywheels have 129 teeth on the ring gear, inertia types have 107 teeth.

Alternative options

The later Verto system introduced in the mid-1980s makes a good alternative for a performance road Mini. This design gives an easier clutch pedal, which might be preferable for daily drivers, however the overall assembly does weigh around 2kg more.

The MED X-Lite Flywheel is the best alternative for full competition Minis, featuring larger cut-outs and an integral ring gear for the starter motor. It is also machined from a higher grade of steel, so has less chance of fretting on the taper of a competition EN40B steel crankshaft.

Fitting advice

We would highly recommend purchasing a complete balanced flywheel assembly and fitting it in one piece to retain the balance. You may wish to lap the flywheel gently to the crankshaft taper before fitment, being careful to remove all traces of paste before final installation.

Firstly lock the engine in position with a Mini flywheel locking tool. Torque the MED pre-Verto flywheel bolt to 130lb/ft, to seat flywheel on the crankshaft taper.

Now undo the bolt, apply a drop of standard-grade thread lock to the thread and re-torque to 130lb/ft. This will ensure the flywheel is properly seated on the crankshaft taper.

Related Products