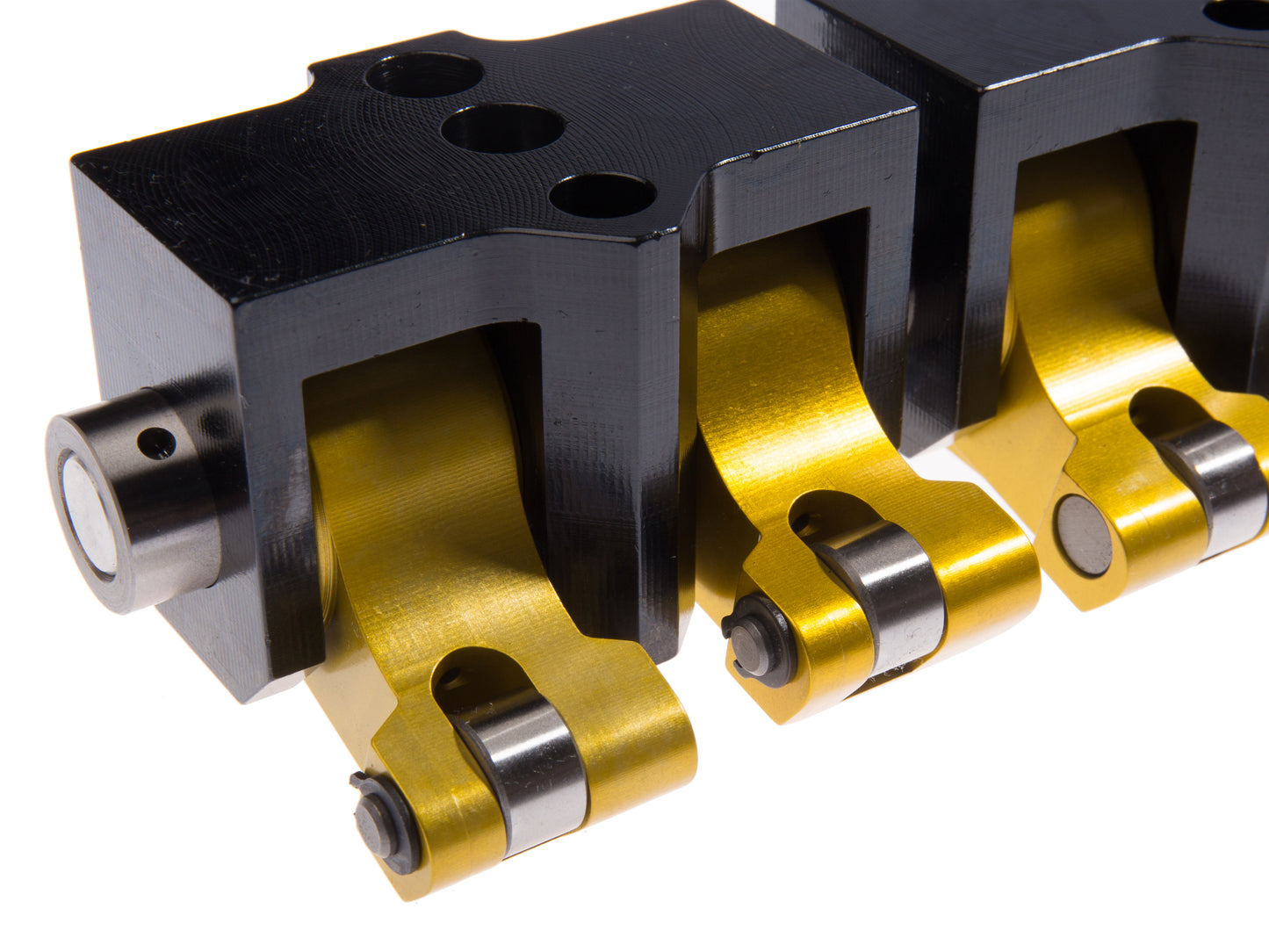

MED 1.5 LDX ROCKERS

Technical Video:View More

Description

In search of the very highest quality and performance, the MED 1.5:1 LDX roller-tip rockers are the result of over a decade of testing and development work on high-end competition engines.

Bridge-section rocker arms, an extra large diameter rocker shaft and 'W' section rocker posts all help to increase torsional rigidity and maintain valve train geometry.

We continue to develop and improve our rocker assemblies to always keep you one step ahead of the competition. Please see the additional information tab for more technical details.

Design features:

- Greater contact area between the rocker shaft and the rocker arm with 17mm diameter shaft.

- Full captive rocker post design to encapsulate each rocker arm between a pair of rocker posts and reduce flex.

- Rocker arms are CNC machined from aerospace 7075 aluminium, which retains the same tensile strength as steel.

- Bridge-section rocker arms reduce flex at high rpm.

- The rocker arms are wider in the front section to give greater roller pin support.

- Roller pins have three locations to achieve maximum rigidity

- The rollers are cylindrically ground to achieve precise valve lift across the head.

- Offset option for full-race heads with offset exhaust valves.

Please note - the arm spacing of our rocker assemblies makes them suitable for 1275, 970(S) and 1071(S) based engines only. They will not suit small-bore (850, 998,1098 etc) cylinder heads.

For extra clearance we would highly recommend an MED rocker cover kit and ARP head stud set to accompany these rockers.

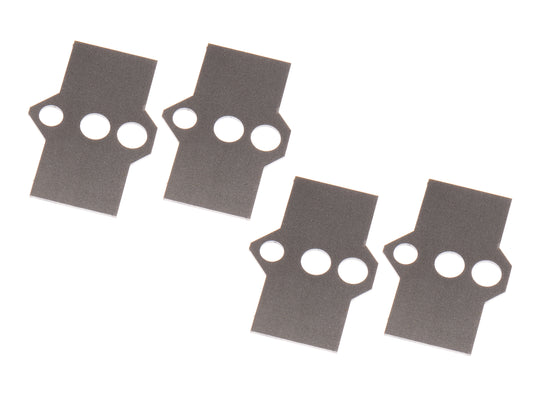

You may also require a set of rocker post shims to perfect valve lift and centralise the rockers over the valves when the head/block faces have been machined.

Frequently Asked Questions

What is the difference between regular MED roller rockers and LDX?

LDX is our most advanced roller rocker assembly, with W-section rocker posts that encapsulate the rocker arms and help to further reduce rocker shaft flex at high RPM levels. We'd consider these as the ultimate competition roller rockers for the 1275-based A-Series engine.

Are MED rockers for road use, or are they just for racing?

Not all A-Series roller rocker assemblies are created equal, and we have gone to great lengths to ensure these are the most durable setup possible, whether it's for a long-distance road trip Mini or full-race car. Take the roller tips as an example, which feature a unique three-way retention technique at the roller pins. The 7075 aluminium arms have a higher tensile strength than many grades of steel, while the enlarged adjuster screw threads are there for ultimate longevity.

What is the benefit of these A-Series rockers over standard?

Extra valve lift, stiffness (durability), reduced side loading and consistency of lift. Standard rockers rarely give consistent valve lift across the head, even when new. After many years of use and wear, lift is likely to be even more inconsistent, so while 1.28:1 is generally given as the standard rocker ratio, a quick check of the valve lift will usually show otherwise. Optimising every aspect of your A-Series engine will enhance performance.

Is the rocker shaft the same as standard?

The assembly is a direct replacement on 1275 engines, but no, the shaft itself is a larger diameter for increased strength. We have also enlarged the rocker arm adjusters for heavy duty performance usage and reliability. All round, these are much stronger than standard rocker assemblies.

Which cylinder heads do these fit?

The MED roller-tip rockers are designed for the 1275 A-Series cylinder head, but will also suit the 1071 and 970 Cooper S engines, which share the same valve stem spacing. If you have a small-bore engine, we make a set specifically to suit, unless of course you are running a 1275 head on a small-bore block - then these will fit no problems. If you are running a more exotic race head with offset exhaust valves, we have a version to suit.

Will these rockers fit inside my standard rocker cover?

Yes these should fit inside a standard steel/tin rocker cover. For thicker-walled aluminium rocker covers, you will need to machine the inside rear edges for clearance, or perhaps take a look at the MED rocker covers, which come machined internally.

Do I need rocker post shims?

Yes it might be a good idea to order a set or two to experiment with. When the cylinder head or block have been machined, the valve seats re-cut, or a combination of all three, it can all affect the rocker geometry on an A-Series engine. The aim should be to achieve the correct valve lift of the camshaft at full lift, roughly indicated by the roller tips sitting centrally (fore and aft) on the valve tip at half lift. If the rocker geometry is incorrect, you will not achieve the desired 1.5:1 ratio between the cam and valve lift figures. Winding the adjusters out to their extremes may also give clearance issues with the pushrods.

Is there anything else I might need?

We always recommend changing the head gasket when removing the rocker assembly, as you may end up disturbing the gasket while loosening off the rear stud nuts. Arm clearance can sometimes be an issue when using the standard head studs and nuts, so an upgrade to ARP head studs and nuts is a good plan.

Are these roller-tip rockers or full roller rockers?

MED rockers are all roller-tip rather than full roller rockers, as we have found this gives the best longevity and accuracy. We run the 7075 aluminium rocker arms direct on the shaft, taking advantage of its larger diameter to spread the load. This is preferable to running needle roller bearings within the arms, from our experience.

Related Products